Those nine months a mom carries her baby are filled with joy, anticipation, and a dose of uncertainty. What the new parents hope for is their bundle of joy to be healthy. Sadly, that is not always the case.

Jennie Wilklow, from Highland, New York, couldn’t wait to meet her daughter. She and her husband were over the moon to hold her in their arms. All the ultrasounds and doctor’s appointment suggested the baby was healthy, so they were eased and never thought sweet Anna would be born with a condition that would change all of their lives forever.

Jennie delivered Anna via C-section at 34 weeks. Doctors told her she looked beautiful and that was all Jennie needed to hear at that point.

Shortly after, the proud mom heard her daughter cry, and that was just another sign that everything was right with her little jewel.

When her husband visited Jennie, he was strangely silent and looked worried and puzzled.

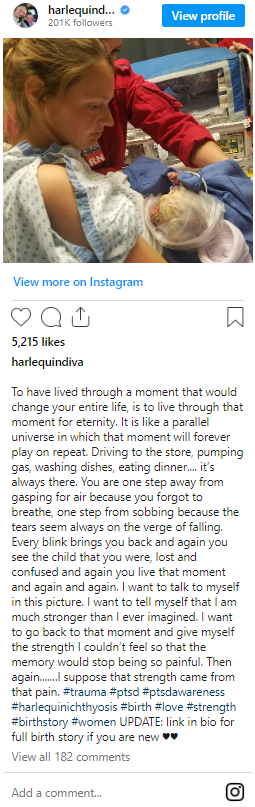

“My husband’s silence scared me; he just sat in shock as the doctor left, and I prodded for more info,” Jennie shared with Cafe Mom.

“He just kept saying, ‘It’s bad.’ What does that even mean? I thought in my head. He told me, ‘Jennie, I looked in her eyes, and she has the most beautiful soul.’”

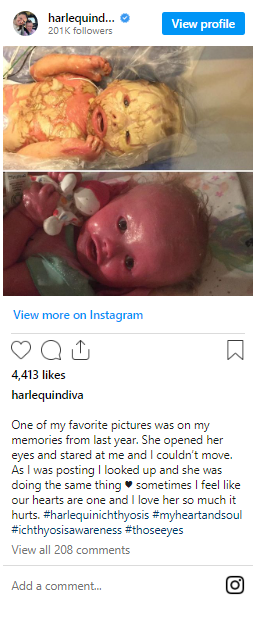

Anna was diagnosed with harlequin ichthyosis, a rare condition that causes thick diamond-shaped plates that are separated by deep cracks. “As they tried frantically to help her, her skin hardened within seconds (of birth). After hardening, it began to split, causing open wounds all over her body,” Jennie told Cafe Mom.

\

Although doctors weren’t sure she would survive, Anna beat the odds and is thriving. “She was beauty in the purest form,” her mom said.

There isn’t cure, and the treatment is quite demanding as it requires constant baths and keeping the skin as much moisturized as possible. “Every couple of hours I covered her with Vaseline and bathed her for many hours of the day. I had dreamed for years about the things my baby would wear, and though it seemed so trivial, it was what I struggled with most,” Jennie said.

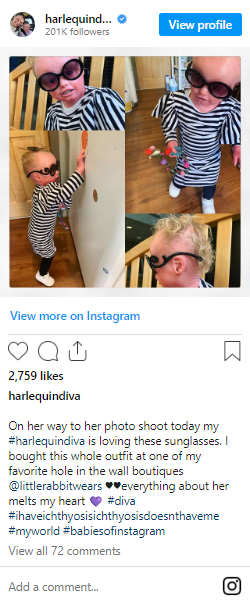

In an attempt to raise awareness about this condition, Jennie posts photos of Anna on her Instagram page harlequindiva. She opens up about the everyday struggles and what it is like to have a child with harlequin ichthyosis.

“Anna captured everyone’s hearts because she is the purest form of perfection. Doing the work every day is simple when I’m doing it for her, and with every new accomplishment, the world celebrates with me,” Jennie told Cafe Mom.

She adds, “I now understand that I was given her because of the love I already carried in my heart for my daughter. Anna was meant for me, and I for her, and together we will show the world what true beauty is.”

Uncovering the Past of This Vintage Treasure

Label makers have evolved remarkably over centuries, transforming from primitive hand-carved labels to advanced digital devices. These indispensable tools have revolutionized organization, manufacturing, and retail. Let’s take a journey through the rich history of label makers, exploring their origins, key innovations, and their impact on industries worldwide.

Label Makers in Ancient Times: The Birth of Organization

In ancient civilizations, the concept of labeling existed long before modern technology. People used primitive methods to mark ownership and identify items. The earliest label-making techniques involved carving or engraving symbols onto materials like wood, clay, or stone. While these labels were far from today’s sleek, customizable options, they served an essential purpose—organizing and identifying items.

These early labels were often attached to goods using strings or primitive adhesives. They were primarily used in trade, where identifying the ownership or contents of goods was crucial. This system, though labor-intensive and limited in design, laid the foundation for the modern labeling systems we use today.

The Rise of Industrial Label Makers: Revolutionizing Production

Fast forward to the Industrial Revolution, and the world of labeling experienced a dramatic shift. The mass production of goods required efficient methods for labeling products, tools, and containers. This gave rise to the first industrial label makers, which were rudimentary machines but significantly more efficient than manual labor.

These early machines were often hand-operated, using interchangeable metal or wooden types to stamp information onto labels. The impact was profound—manufacturers could now label large volumes of products quickly and accurately, reducing human error. This period marked the beginning of automated labeling systems, which streamlined production processes and set the stage for modern industry standards.

Innovations in Label Making Technology: The Digital Leap

As industries grew and technology advanced, so did label-making technology. One of the most significant breakthroughs was the advent of digital label printers. Unlike the manual, labor-intensive methods of the past, digital printers offered precision, speed, and customization.

Digital label printers employ techniques like inkjet or laser printing, allowing businesses to produce high-quality, full-color labels. Whether it’s a simple barcode or a complex design, digital printing offers endless customization options, including various shapes, sizes, and materials. This innovation has been a game-changer for industries like retail and manufacturing, where efficient and accurate labeling is crucial.

Additionally, label design software became widely available, empowering users to create professional-looking labels without specialized training. These programs offer templates, fonts, and graphic options, making it easier than ever to align labels with branding strategies. Features like barcode generation and database integration have further enhanced productivity, enabling seamless tracking of inventory and products.

The Impact of Label Makers on Retail and Packaging

Label makers have significantly influenced the retail and packaging industries. Walk into any retail store today, and you’ll find aisles filled with neatly labeled products, thanks to modern label makers. These labels not only provide essential information but also play a role in brand identity and customer engagement.

In retail, efficient labeling helps consumers find products more easily, streamlining their shopping experience. Clear, well-organized labels ensure that items are correctly identified, reducing confusion and enhancing customer satisfaction. Additionally, the ability to create customized labels has enabled retailers to elevate their branding efforts, ensuring that labels are consistent with their visual identity.

In packaging, label makers have improved accuracy and compliance with industry regulations. Manufacturers can quickly produce detailed labels that include product information, safety instructions, and regulatory requirements. This has enhanced consumer trust, as clear labeling ensures transparency regarding product contents and origins.

Label Makers During the Industrial Revolution: A Game Changer

The Industrial Revolution was a pivotal period for label-making technology. As factories became more mechanized, the demand for efficient labeling systems surged. Early label makers of this era were simple machines designed to imprint basic information onto items like crates and containers.

These machines drastically improved efficiency compared to handwritten labels, which were prone to errors. Industrial label makers made it possible to apply consistent, legible labels in large quantities, reducing mistakes and enhancing the organization of goods. This advancement was a critical step in modernizing industrial processes and logistics.

The Evolution of Label Makers in the Digital Age

In the digital age, label makers have undergone yet another transformation. With the rise of computerized systems, the manual label machines of the past are being replaced by faster, more efficient digital devices. These computerized label makers have automated much of the process, allowing businesses to produce labels with minimal human input.

One of the most significant advancements in this era has been the integration of wireless and mobile technologies. Modern label makers can now connect to smartphones, tablets, and computers, enabling real-time label printing from virtually anywhere. This level of convenience has made it easier for businesses to keep up with the fast-paced demands of today’s market, whether in retail, manufacturing, or logistics.

The Role of Label Makers in Enhancing Productivity

In today’s workplaces, label makers are indispensable tools for enhancing organization and productivity. From labeling files and folders to organizing storage spaces, these machines offer unmatched flexibility and efficiency. Modern label makers allow users to customize labels with various fonts, colors, and symbols, creating a visually appealing and practical organizational system.

The biggest advantage? Time-saving capabilities. Employees no longer have to handwrite labels or struggle to maintain legibility across different departments. Instead, with just a few clicks, they can produce professional-looking labels that help streamline daily tasks and maintain order. This boost in productivity translates to cost savings and improved operational efficiency across various industries.

Conclusion: The Unstoppable Evolution of Label Makers

From the ancient world’s carved stones to today’s sleek digital devices, label makers have come a long way. These tools have transformed industries, improving efficiency, organization, and productivity in ways that couldn’t have been imagined centuries ago. As technology continues to advance, the future of label makers looks bright, with possibilities like AI-driven designs and smart label integration on the horizon. One thing is certain: label makers will remain an essential part of both personal and professional organization, helping industries stay efficient and well-organized for years to come.

Leave a Reply